When we talk about the importance of tools, the small but highly practical product of the glue needle is often overlooked. But in different working scenarios, a suitable and efficient glue needle is the key to solve the problem. Today we will learn more about the four types of glue needles-full hook glue needles, half hook glue needles, question mark glue needles and solid round glue needles, and uncover the design secrets and scope of application behind them.

The first to appear is the full hook glue needle, known for its excellent stability. This glue needle is designed to be completely bent into a hook shape at both ends, providing excellent support in the link of material fixation. Whether it is hand-made or large-scale industrial projects, it can firmly grasp the required items and prevent sliding or shifting. Therefore, it is an irreplaceable good helper for work that requires precise control.

Next is the more flexible half-hook glue needle. As the name suggests, only one end has a hook shape and the other side is more straight. Such a configuration allows it to still function on irregular surfaces or in narrow spaces. For example, in the process of furniture repair encountered difficult to reach the position, half hook glue needle can easily meet this challenge.

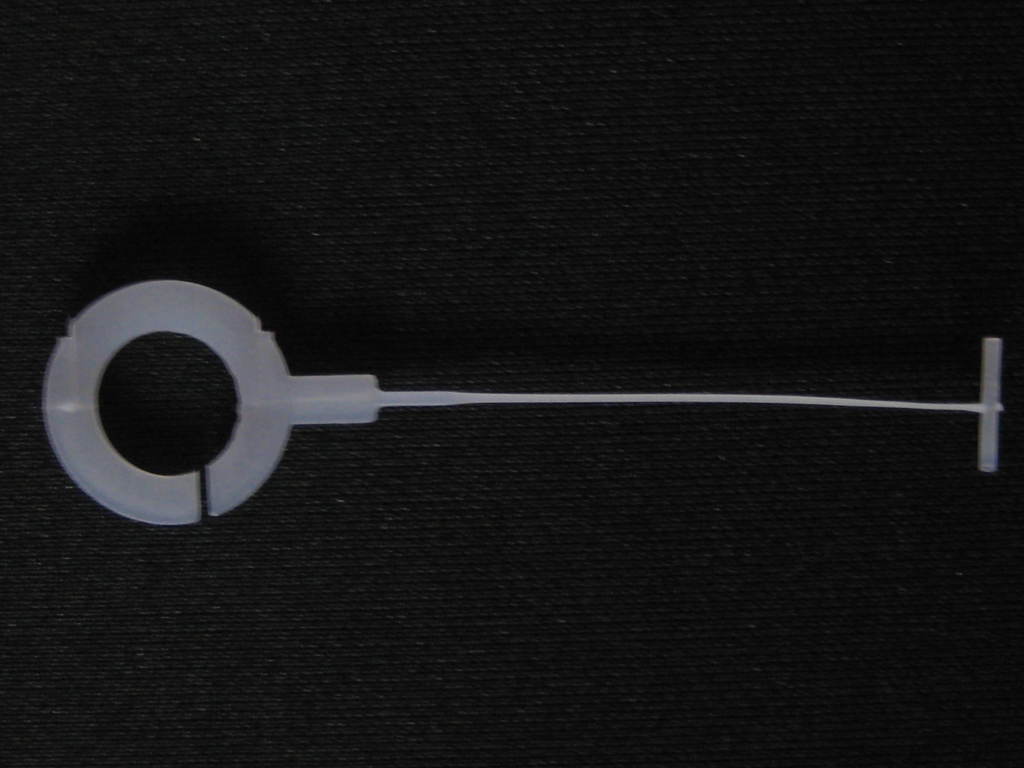

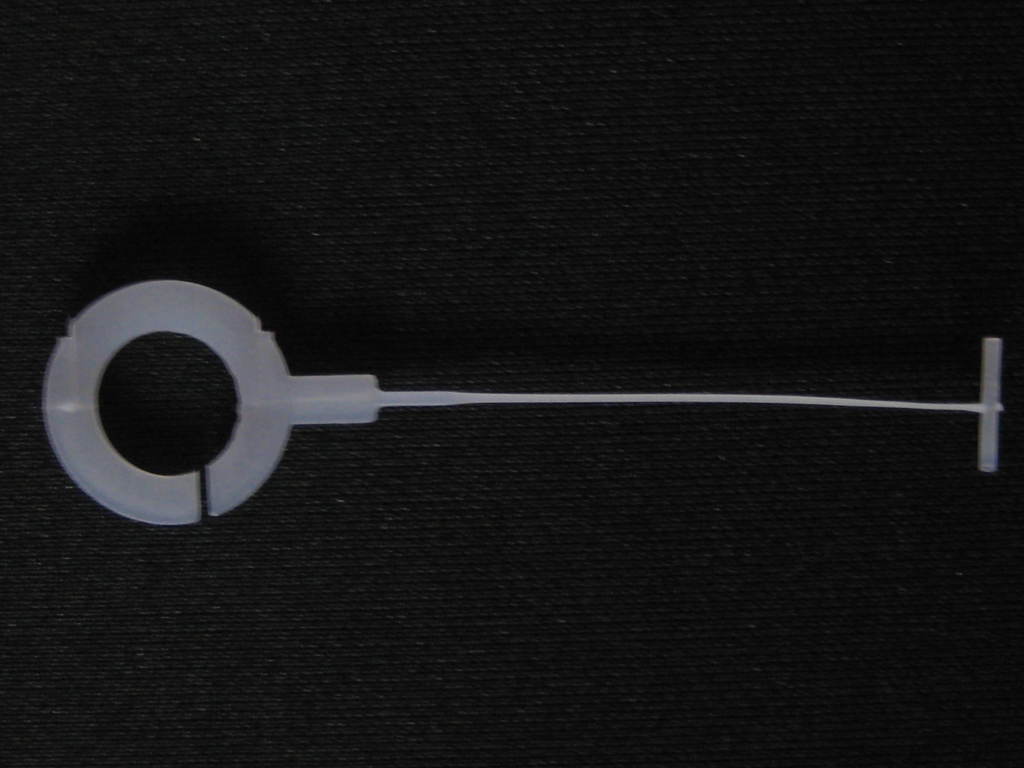

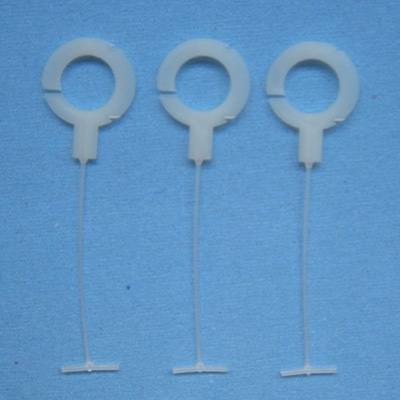

Let's take a look at the unique question mark glue needle. It is called "question mark" because the whole shape resembles a big English symbol '?'. This particular form makes this type of glue needle particularly good at dealing with targets with curved edges. When faced with certain situations that cannot be handled by traditional methods, choosing a suitable question mark glue needle may make you get twice the result with half the effort.

the last thing I have to mention is the solid rubber needle with strong strength! Unlike the light and dexterous images of the other three, this type of glue needle has a strong and thick body structure, which can withstand greater pressure loads. If you are looking for a solution that can be used continuously in a high-strength environment, then solid rubber needles are undoubtedly a wise choice.

In fact, each of the above-mentioned glue needles has its own clear application field and excellent performance. For example, in the sewing industry, full hook glue needles are often used for fabric clamping. In the construction team, solid round glue needles are more relied on to complete tasks such as wood splicing...

In order to help you better decide which category is your favorite, here is a concise and to the point guide:

- it is very important to make judgment after determining the specific purpose;

- Consider whether the operating environment is special (for example, the model that is easy to rust should not be selected in humid areas);

- Give priority to the merchants with good brand reputation and perfect after-sales service within the budget.

I hope the above information will give you confidence in your future purchasing decisions and find the perfect partner for your needs!