Discover the Best Glue Needles: Full Hook, Half Hook, Question Mark & Solid Round Designs

When it comes to precision adhesive application, the right glue needle can make all the difference. Whether you're a DIY enthusiast, a professional craftsperson, or an industrial engineer, choosing the correct type of glue needle ensures clean, accurate, and efficient results. From intricate craftwork to heavy-duty repairs, the design of the needle plays a crucial role in how well the adhesive is applied and how effectively it bonds. In this article, we explore the unique benefits of four top-performing glue needle designs: Full Hook, Half Hook, Question Mark, and Solid Round — and help you decide which one suits your needs best.

Why the Right Glue Needle Matters

Glue needles are far more than simple dispensing tools — they are precision instruments that influence the flow, control, and distribution of adhesive materials. The shape and structure of the needle affect how easily you can reach difficult areas, how smoothly the glue flows, and how well it adheres to surfaces. Whether you're assembling a delicate model or sealing a joint in an industrial setting, the choice of needle can significantly impact the quality of your work.

Full Hook Glue Needle: Precision for Complex Applications

The Full Hook design is engineered for scenarios where maximum control and adhesion are essential. Its curved tip allows for precise delivery of glue into crevices and tight spaces, while the hook shape helps prevent backflow and unwanted drips. This makes it ideal for applications like furniture restoration, model building, and multi-layered craft projects where glue placement must be exact.

Users who work with thick or high-viscosity adhesives often find the Full Hook needle to be their go-to tool. Its structure ensures a steady flow and minimizes clogging, offering a clean finish even in the most intricate applications.

Half Hook Glue Needle: The Versatile Middle Ground

For those who need a balance between flexibility and control, the Half Hook needle is an excellent choice. Designed with a partially curved tip, it provides enough precision for detailed work while maintaining a smooth, consistent flow. This makes it particularly popular among DIYers and hobbyists who switch between fine craftwork and light assembly tasks.

Its compatibility with medium-viscosity adhesives makes it suitable for a wide variety of projects, from scrapbooking to light woodworking. The Half Hook needle is praised for its ease of use and forgiving nature, especially for those who are still building their adhesive application skills.

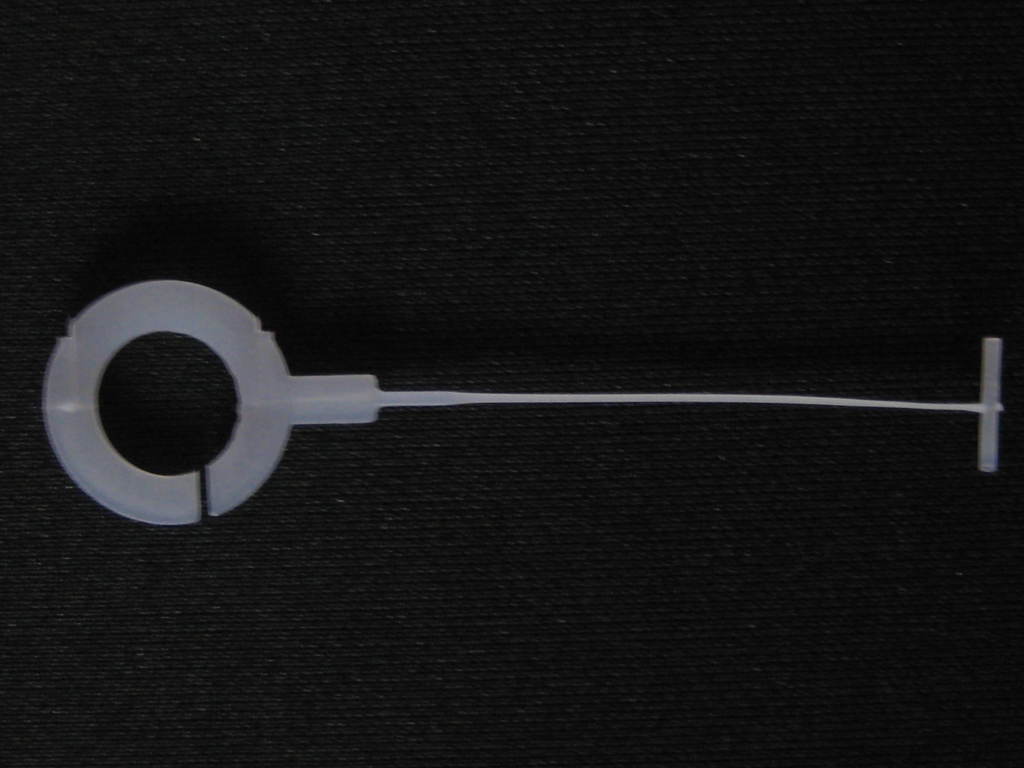

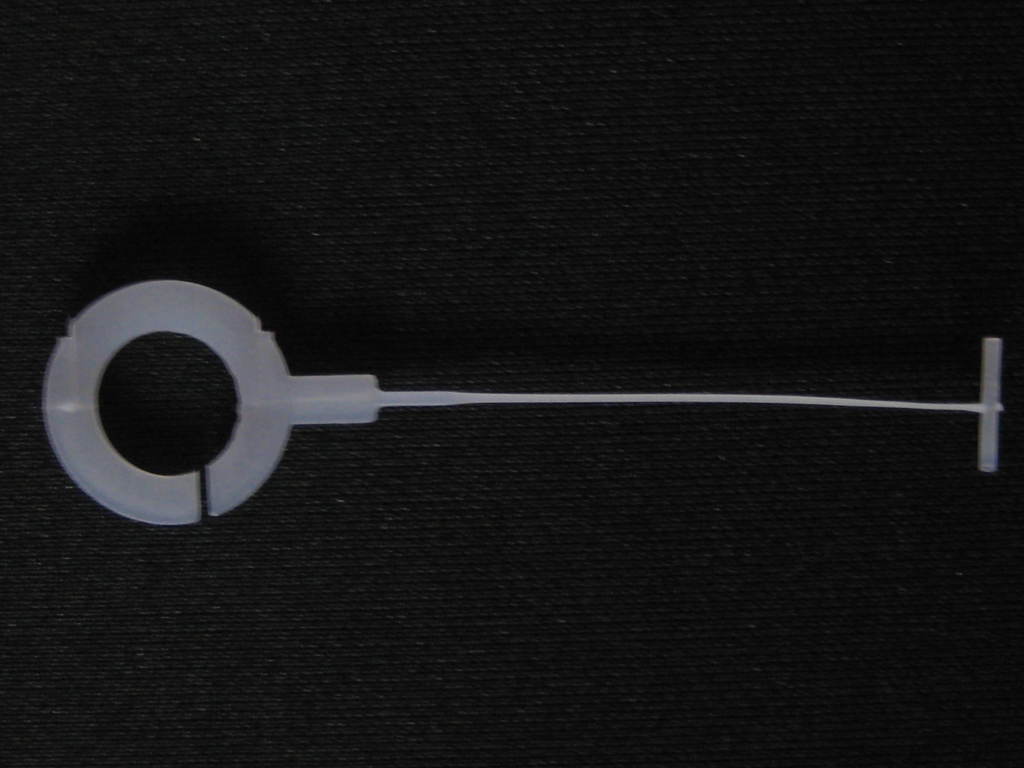

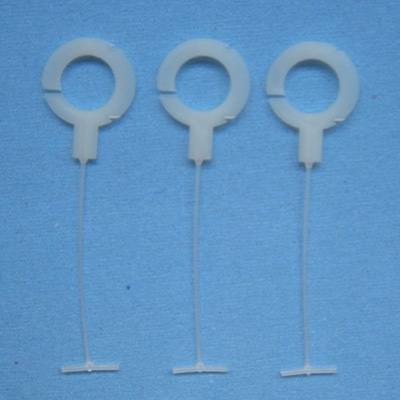

Question Mark Glue Needle: Designed for Curves and Corners

True to its name, the Question Mark needle features a uniquely curved shape that resembles the punctuation mark. This design is especially effective when working with curved surfaces, uneven textures, or hard-to-reach corners. Crafters and electronics manufacturers often turn to this needle when dealing with intricate shapes or small components that require careful adhesive placement.

Its ergonomic form allows for better maneuverability, making it a favorite among artisans and repair technicians. Whether you're sealing a circuit board or adding a decorative detail to a handmade piece, the Question Mark needle offers the control and reach needed for complex tasks.

Solid Round Glue Needle: Simplicity Meets Efficiency

For applications that demand speed and consistency, the Solid Round needle is the ultimate solution. With a straight, cylindrical tip, this design delivers a uniform flow of adhesive, making it perfect for large surface coverage or high-volume dispensing. It’s a staple in industrial settings where reliability and efficiency are paramount.

Thanks to its straightforward design, the Solid Round needle is also incredibly easy to clean and maintain, making it a cost-effective option for frequent users. Whether you're sealing packaging or assembling components on a production line, this needle ensures a fast, clean application every time.

Choosing the Right Material and Size

While the shape of the needle is crucial, material and size also play a significant role in performance. Stainless steel needles offer durability and resistance to wear, making them ideal for heavy use. Plastic needles, on the other hand, are lightweight and cost-effective, often preferred for one-time projects or disposable applications.

Size matters too — the internal diameter of the needle determines the flow rate and the thickness of the adhesive it can handle. Matching the needle to your glue gun and glue type ensures optimal performance and reduces the risk of clogging or uneven application.

Expert Picks: Choosing Based on Your Needs

For beginners, the Half Hook or Solid Round needle is often the best starting point, offering simplicity and consistent results. Crafters and detail-oriented artists may lean toward the Question Mark or Full Hook designs for their precision. Industrial users and engineers typically favor the Solid Round or Full Hook needles for their reliability and performance under demanding conditions.

Pro Tips for Getting the Most Out of Your Glue Needle

Angle and pressure are key when applying adhesive. Holding the needle at a slight angle helps guide the glue precisely where it's needed. Controlling the pressure ensures even flow without over-application. After use, cleaning the needle promptly prevents buildup and prolongs its lifespan. Keeping a few different needle types on hand allows for quick switching between tasks, ensuring you're always equipped for the job at hand.

What’s Next for Glue Needle Innovation?

As industries evolve, so do the tools we use. The future of glue needle design includes biodegradable materials, smart glue guns that adjust flow based on needle type, and customizable designs tailored to user feedback. These advancements aim to enhance user experience, reduce environmental impact, and meet the growing demands of both hobbyists and professionals alike.