In the world of adhesives, the choice of glue needle can make a significant difference in the outcome of your project. Whether you're a hobbyist working on a delicate craft or an industrial manufacturer assembling high-stress components, selecting the right glue needle ensures optimal performance, precision, and durability. Let’s explore the unique characteristics and applications of four popular types: full hook, half hook, question mark, and solid round glue needles.

Why Glue Needle Selection Matters

Glue needles are more than just applicator tips — they determine how evenly the adhesive flows, how precisely it can be placed, and how well it bonds with the surface. From delicate paper crafts to high-pressure industrial applications, the right needle can transform a messy process into a clean, efficient, and professional one. Understanding the differences between glue needle types empowers users to make informed decisions that enhance both the quality of their work and the efficiency of their workflow.

Full Hook Glue Needle: The Versatile Workhorse

The full hook glue needle features a curved, hook-like tip that allows for controlled glue flow while maintaining a firm grip on the adhesive. This design makes it particularly effective when working with medium to high viscosity glues, where maintaining a steady stream without drips is essential. Ideal for applications like model building, packaging sealing, and general-purpose crafts, the full hook needle provides a balance between precision and strength. Its curved edge helps guide the glue exactly where it’s needed, making it a favorite among both professionals and DIY enthusiasts.

Half Hook Glue Needle: Precision with Flexibility

Offering a more refined application than the full hook, the half hook glue needle is ideal for users who require accuracy without the need for extreme bonding strength. Its semi-curved tip delivers a smooth and consistent glue line, making it especially useful in electronics assembly, light fabric bonding, and other tasks where precision is key. The half hook allows for easy control over the adhesive, ensuring clean lines and minimal waste. Whether you're assembling circuit boards or crafting jewelry, this needle provides the flexibility and finesse needed for detailed work.

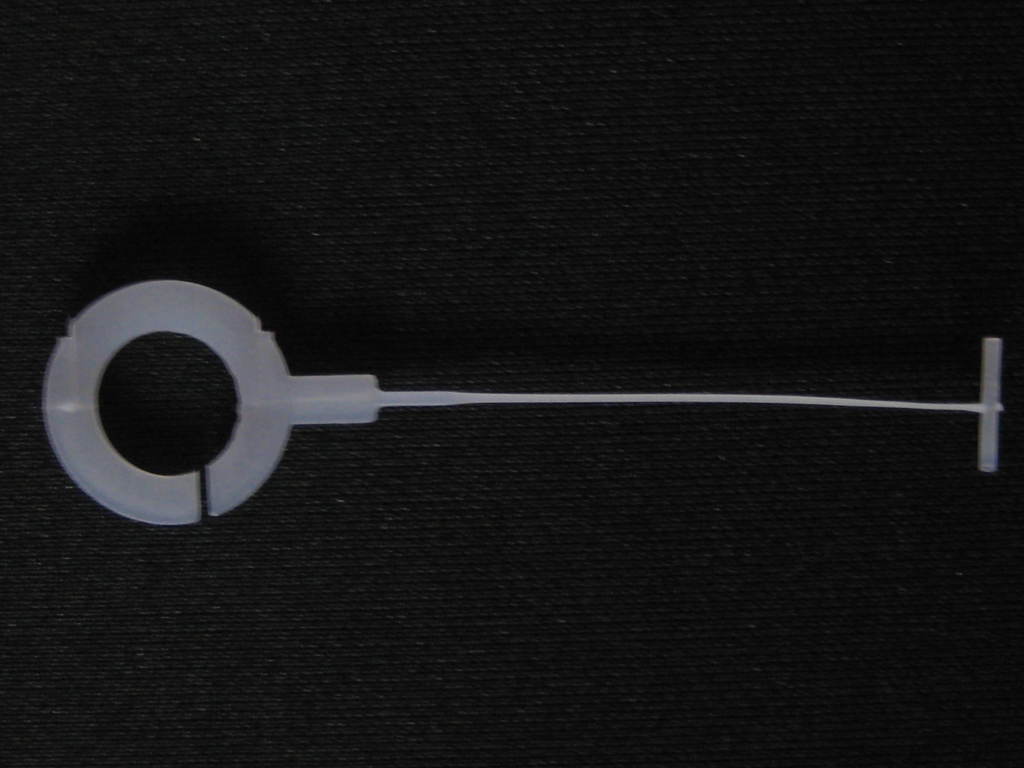

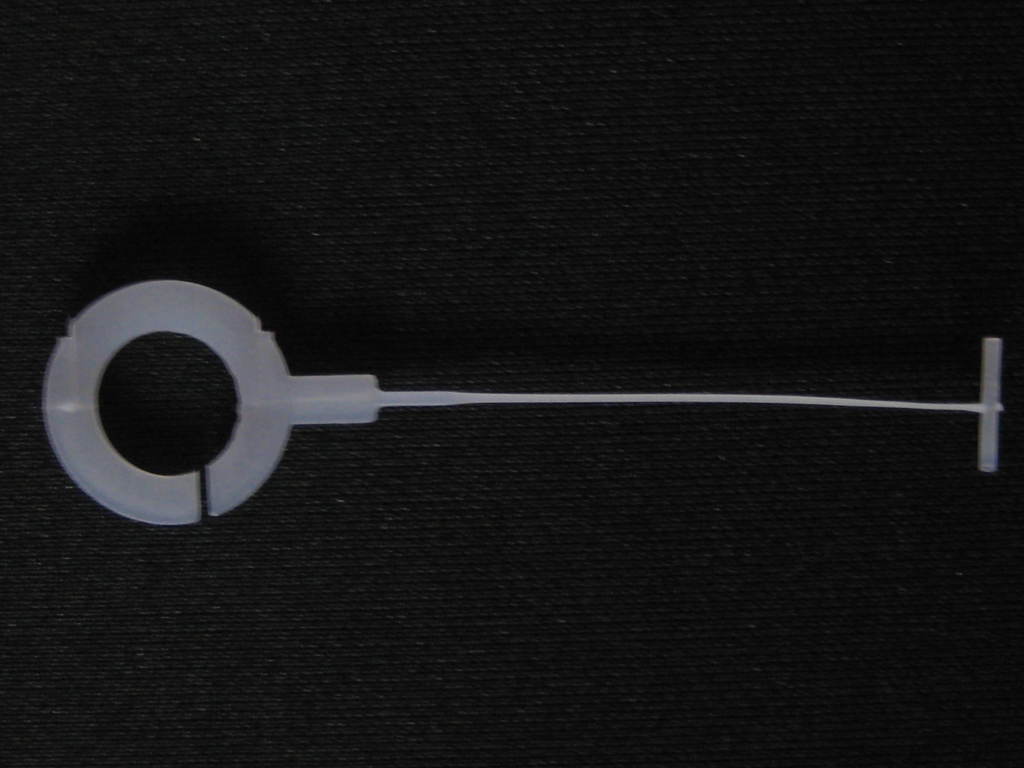

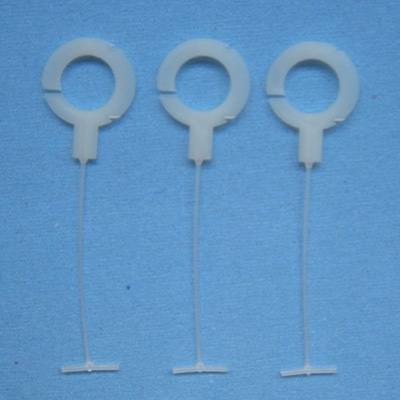

Question Mark Glue Needle: The Artist's Choice

Named for its distinctive shape resembling a question mark, this glue needle is a favorite among artisans and designers who require exceptional control over adhesive placement. Its unique curvature enables precise navigation around curves and corners, making it ideal for intricate crafts, beadwork, and fine art projects. The question mark needle ensures that glue is applied exactly where needed without spreading beyond the intended area. Whether you're working on a complex mosaic or a delicate embroidery piece, this needle helps you achieve seamless, invisible bonds that enhance the final look of your creation.

Solid Round Glue Needle: The Industrial Powerhouse

When it comes to heavy-duty applications, the solid round glue needle stands out for its durability and strength. With a thick, cylindrical tip that resists wear and deformation, this needle is designed for high-pressure industrial use. It’s commonly used in automotive assembly, construction, and furniture manufacturing, where a strong, long-lasting bond is crucial. The solid round needle ensures even glue distribution under stress, providing structural integrity and reliability in environments where failure is not an option. For professionals who demand performance and longevity, this needle is an essential tool.

Choosing the Right Glue Needle for Your Project

Each type of glue needle brings unique advantages to the table. The full hook offers versatility, the half hook brings precision, the question mark excels in detail work, and the solid round guarantees strength. When selecting the right needle, consider the type of glue you're using, the materials you're bonding, and the environment in which the bond will be tested. For example, high-viscosity adhesives may require a full hook or solid round, while fine arts projects benefit from the control of a question mark or half hook needle. Understanding these nuances can help you avoid common mistakes like uneven application, excess glue waste, or weak bonding.

Pro Tips for Maximizing Glue Needle Performance

Even the best glue needle won’t perform well if not used correctly. Start by ensuring the needle is securely attached to the glue gun or dispenser. Clean the needle after each use to prevent clogging and maintain consistent flow. If working with thick adhesives, consider preheating the glue slightly to ensure smooth application. Experts also recommend testing on a scrap surface before applying glue to your final project. Proper maintenance not only extends the life of your glue needles but also ensures that every application is as clean and effective as possible.

The Future of Glue Needle Technology

As adhesive technology continues to evolve, so too do glue needles. Innovations in materials and design are paving the way for smarter, more efficient application methods. From temperature-resistant needles for high-tech manufacturing to eco-friendly, recyclable options for sustainable crafting, the future looks promising. Staying updated on these advancements can give both hobbyists and professionals a competitive edge, allowing them to achieve better results with less effort and waste.